Services

We offer solutions that are practicable and tailored to the specific case

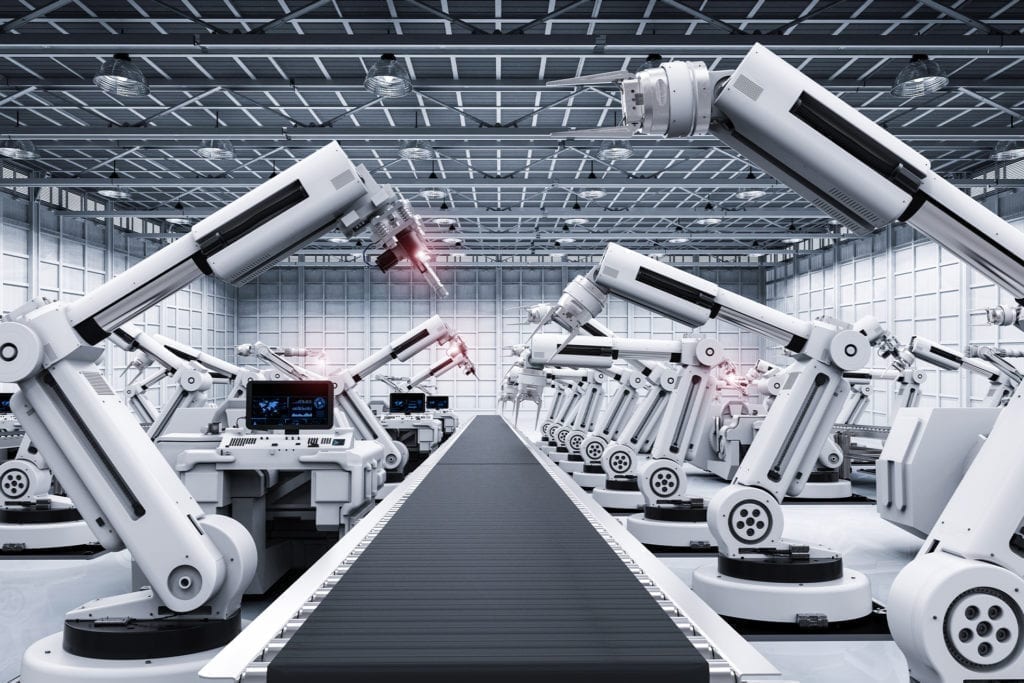

In the automotive, industrial electronics and automation technology sector we make your innovations possible, as we transform your ideas into electronics: individual, cooperative and cost-optimised. We accompany you from developing your idea to constructing a prototype to serial production. Everything from a single source, everything from a single partner. Our services range from development to prototype construction to serial production as well as contract assembly of your assemblies.

Overview of our Services

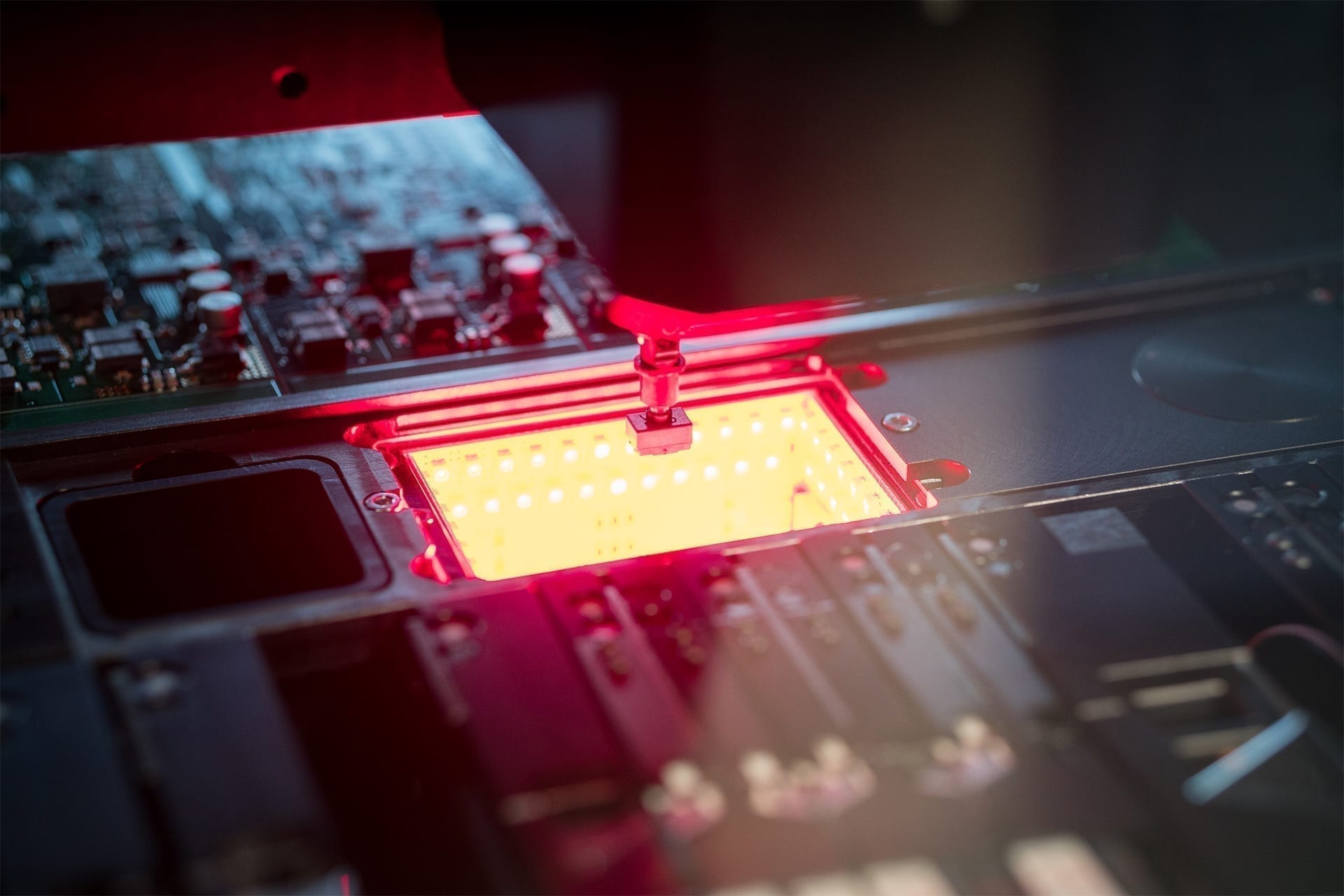

- Development and production of system electronics for the automotive and industrial sector

- Installation of own control electronics in the vehicle

- Electrical and mechanical planning/construction as well as mounting

- SMD and THT assembly/contract production

Control Technology in our Areas of Application Einsatzgebieten

Special Purpose Vehicles

Whether fire engine, ambulance, police or aid organisation –

Agricultural and Construction

Inomatic is your contact for control technology in the agricultural and construction machinery sector. Controls with which vehicle and GPS data can be transmitted online up to control panels tailored especially to your needs. As a systems supplier, we offer you onehundred percent customer service as well as high-quality products.

Find out moreCaravan and Motorhomes

Inomatic is your certified system supplier for control technology in the caravan and motor home sector. With an extensive portfolio of various serial products, reliable customer service and very high quality standards, we always stand by your side to find a tailor-made solution for your needs. See for yourself.

Find out moreMunicipalities

More and more CAN-bus technology is also being used in municipal vehicles, and this is exactly where

Industry

As a systems supplier for control technology,

Security Vehicles

Whether in the money transport sector or in the military sector: the