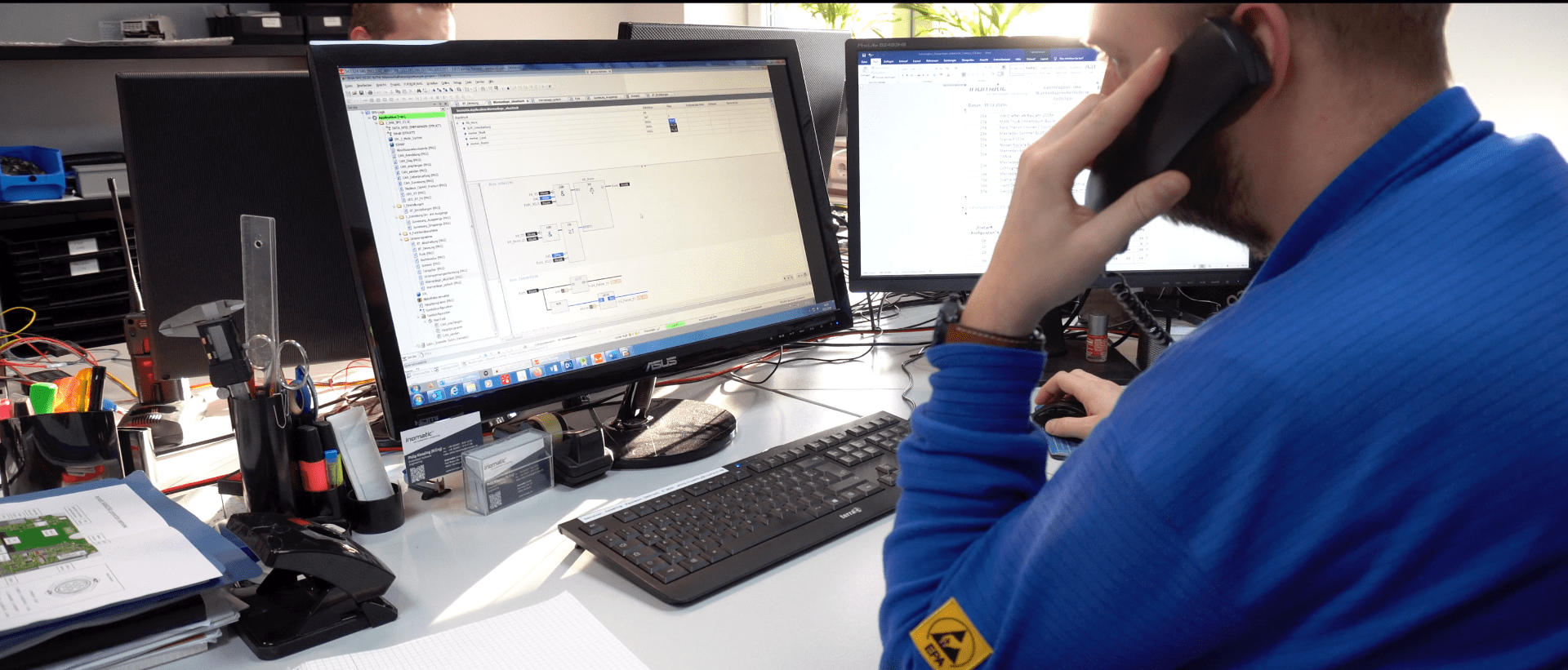

Customer Service

We help you to find solutions. Whether it is about support in the form of problem solutions for fault isolation, information on the correct connection of devices or a required spare part. We are there for you quickly and easily, since we deliberately keep the paths between development, production and service short.

Register now to receive your document

Overview of our Services

- Spare Part Logistics

- Claims Management

- Repair Management

- Repair and Error Database

Service Procedure

You contact our service department and inform us about the problem you encountered. We swiftly decide how we can help you. In case you need a spare part, it is sent to you including a DHL-parcel stamp and a return shipping note. This saves you expenses and minimises your effort.

As soon as the defect device reaches our premises, we perform a thorough incoming components inspection. Then and there it is decided as to whether this is a warranty case.

Repairs

Do you request repairing a device made by us? We gladly provide you with a free cost estimate. Send us the device, we will check it, provide you with a cost estimate, and you decide on carrying out the repair. After your release of the repair and its completion, the device will be returned to you, on request also as express delivery.

Meeting the highest Quality Requirements

Modern production and automated testing procedures as well as our personal interest in good and reliable products provide the basis for meeting the highest quality requirements, to which we are committed.

IPC 601

We commit to the highest quality requirements. Modern production and automated testing procedures as well as our personal interest in good and reliable products provide the basis. In order to guarantee this, we develop and produce according to the IPC guidelines.

One key aspect is the IPC-A-610 norm in production. This serves as a guideline for testing the assemblies and the evaluation of the production process.

Automated Tests

After the soldering process, assemblies are subjected to various tests. We rely on the following components and testing procedures:

AOI Check (Automatic Optical Inspection): A check of all soldering and components (value/position/polarity) is carried out here.

ICT Examination (In Circuit Test): An electrical test and partly also the programming of assemblies is automatically carried out.

Optimally equipped

Our service and test facility is equipped with modern measuring instruments. Among others, digital storage oscilloscopes and 2-vision microscopes are used here in order to meet the various technical, electronical and mechanical challenges.

Naturally, all production stations are designed in an ESD-supporting manner. The production, storage and testing areas are protected EPA zones, in order to protect the electronical components.